Test Your Material

See And Feel The Precision Of Kern Lasers. Let's Process Your Material.

Kern Laser Systems is a leading manufacturer of large format laser cutting and laser engraving equipment. Since opening their doors in 1982, Kern is proud to have installed thousands of large format laser cutters and engravers worldwide. Designed and manufactured with pride in the USA, Kern specializes in large format fiber and CO2 laser cutting systems. Additionally, Kern’s machines are capable of processing plastic, foam, acrylic, textiles and metal cutting.

See And Feel The Precision Of Kern Lasers. Let's Process Your Material.

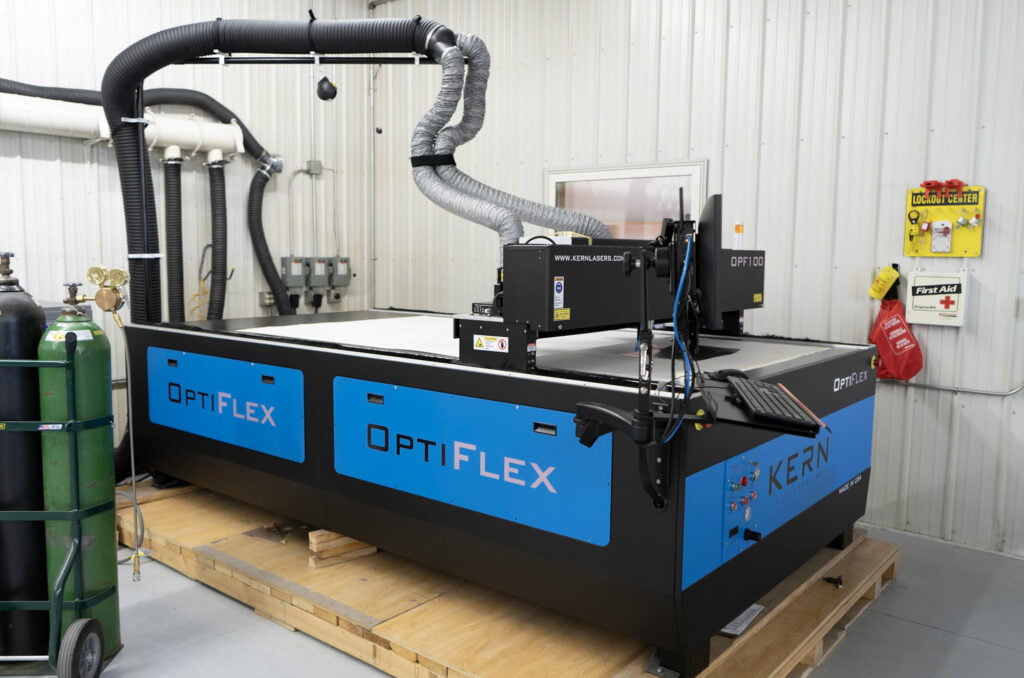

The OptiFlex is a high performance, large format laser cutting and engraving system. This is the most popular and versatile machine in Kern’s product line. The OptiFlex is ideal for processing of metal, acrylic, wood, textiles and foam while also featuring high-speed engraving capabilities.

Kern’s LaserCELL is a complete laser engraving and laser cutting machine featuring the perfect blend of performance and safety. Its fully enclosed (Class 2) design allows the LaserCELL to be placed in high-traffic areas such as busy factory floors and university classrooms. This system makes and amazing acrylic cutting laser setup.

Our FiberCELL is a compact sheet metal cutting laser capable of cutting stainless steel, mild steel, aluminum, brass and copper. A Class 2 safety enclosure allows the CNC laser system to be placed in high-traffic areas such as busy factory floors and university classrooms.

The EcoFlex is an entry-level, large format laser engraving and cutting system. The EcoFlex is also well-known as a highly-productive CO2 laser system offered at an economical price.

Kern’s entry-level MICRO laser cutter and laser engraver system features a small format work area. Still, it can be equipped with the same powerful CO2 lasers as our large format laser cutting equipment. Perfect for shops with limited space that require a powerful CO2 laser cutting machine.

Double or triple your cutting production! The OptiDual is a high production laser cutting machine. This model features two ( or three) lasers mounted on a single gantry. Both lasers’ output power can be matched within the KCAM software. This ensures that the parts being produced are similar in size, accuracy and quality. This large format laser system is available in a wide range of table sizes.

An important part of any laser system that often gets overlooked is the vacuum blower system. An adequate vacuum system is essential to remove the fumes and small debris that are created…

The KT650 can go up against any similar CO2 laser on the market as it offers the most power, pound for pound, in a compact, convenient package. The most powerful laser engraver on the market.

What is a company without its employees? Who would be there to help customers? To build products? To pack and ship replacement parts? At Kern Laser Systems, we don’t like to imagine…

Personal and Business choices are like people. They come in all shapes and sizes. When laser shopping, some clients choose a foreign-made machine while others elect to purchase a Kern “Made in America” laser system. Choosing between a foreign-made and US-made large format laser system is one many businesses have to make, but the differences between these two options are, frankly, a world apart. Rich Domikis, Managing Partner of Cabin Digital LLC, a satisfied Kern Laser owner and also the purchaser of a foreign-made laser systems shares his story about his experiences with both.

Teaming up with Geneva Capital certainly presents great new finance options on our large format laser cutting and laser engraving systems. Additionally, financing makes it easy to get the equipment you need, while experiencing the benefits and tax savings of leasing.